In Israel, a 16 year-old girl had been diagnosed with Ewing Sarcoma, a rare form of cancer that causes bone degeneration. Over time, she had reported significant pain and swelling in her right shoulder. After further analysis, an MRI concluded that her scapula bone within her right shoulder had experienced extreme bone loss. Being that the scapula facilitates shoulder joint movement and stabilization, the need for a fix had become critical.

Presenting their solution at Hexagon Live 2025 last week in Las Vegas, Nevada, PTC and Hexagon Technologies discussed how they collaborated to 3D print a new scapula for the patient. For PTC the work started with an additional MRI and the use of the company’s Creole CAD software. The MRI was used to scan the patient’s fully functional left shoulder. Using the software’s mirror function, the team created an identical copy that could be 3D printed. It was a slightly different process for the team than standard reverse engineering, because it was a complex assignment.

The 3D-printed scapula has to be strong and capable of attaching to all 17 muscles that surround the bone. The goal was to keep the same shape and size, but ultimately replace the mechanics. Kinematics and mechanical properties were top of mind for the engineers, as the replacement couldn’t be too light or too heavy, so the team chose to print the part in titanium.

Compared to bone, titanium is three times greater in density, but also nine times greater in strength. So, the print didn’t have to be quite as large, but still needed the correct attachment points. To meet these specifications, the PTC design team removed the interior of the bone, creating a triangular replacement that was hollow.

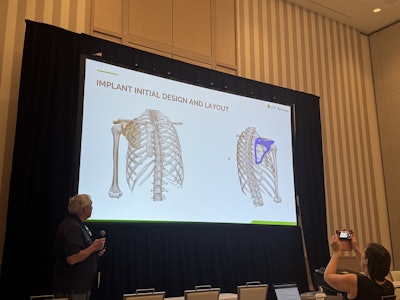

Goodwin shows the layout of the scapula implant’s design.Devon Verbsky

Goodwin shows the layout of the scapula implant’s design.Devon Verbsky

The PTC team designed the new scapula to be fully functional, creating holes where the muscles would be attached, and reinforcing areas like those that could rub against bone. Using Creole’s analysis capabilities, the PTC team tested stresses and load. The biggest concern was deformation, making sure the 3D-printed scapula wouldn’t bend too much or too little.

Hexagon Strategy and Business Development Director of Additive Manufacturing Solutions Mathieu Perrenou said, “Your body adapts to everything, but if your implant is too strong, everything around the implant will weaken. The body will realize the implant can take more force. So the idea is to mimic the behavior of bone with titanium.”

When the project was passed to Hexagon, the company marched toward full production by simulating the printing process, ensuring full debugging of the end-product. Hexagon’s Air Studio software was used to model the ideal printing position, optimize print time and correct distortions—the simulation also protects against shrinking and deformity to ensure proper end-shape.

Overall, these simulations helped Hexagon save a lot of time prior to final print processing— print time took just over a day to fully form the scapula.

After the part was completed, surgeons implanted the scapula, which has given the patient full functionality from day one. From the initial scan to the final surgery, the total process took just less than four days to complete.

Goodwin presents the outcome of the operation.Devon Verbsky

Goodwin presents the outcome of the operation.Devon Verbsky