The cost of a type of aerogel, the world’s lightest solid material, has been cut astronomically thanks to Chinese researchers.

Aerogels have long been used by space agencies such as Nasa for their high porosity and excellent insulating properties. But producing the material has always been expensive.

According to information on Nasa’s website, the aerogel used in Nasa spacecraft cost around US$1,000 per litre back in 2005. The price has dropped with advancements in synthetic technologies, but high-performance silicon carbide (SiC) aerogels remain expensive from a few hundred to several thousand dollars per litre.

Now Chinese researchers say they have managed to lower the production cost of SiC aerogel to just US$0.70 per litre.

Even in China, where aerogel manufacture is cheaper due to the economies of scale, this new technology can make the material for about one-hundredth of the cost and at ten times the speed.

Their study was published on August 13 in peer-reviewed journal Nature Communications.

It is a leap forward in the material’s accessibility, according to the researchers.

A single layer of aerogel can protect human skin from direct flame. Modern advancements have further refined aerogels into films or sprays, broadening their applications to include fuel cells and semiconductors.

The research team, led by Professor Li Jiantao from the Technical Institute of Physics and Chemistry at the Chinese Academy of Sciences (CAS) and assistant professor Dong Yanhao from Tsinghua University’s school of materials science and engineering, brought down the cost with a new combustion synthesis technique.

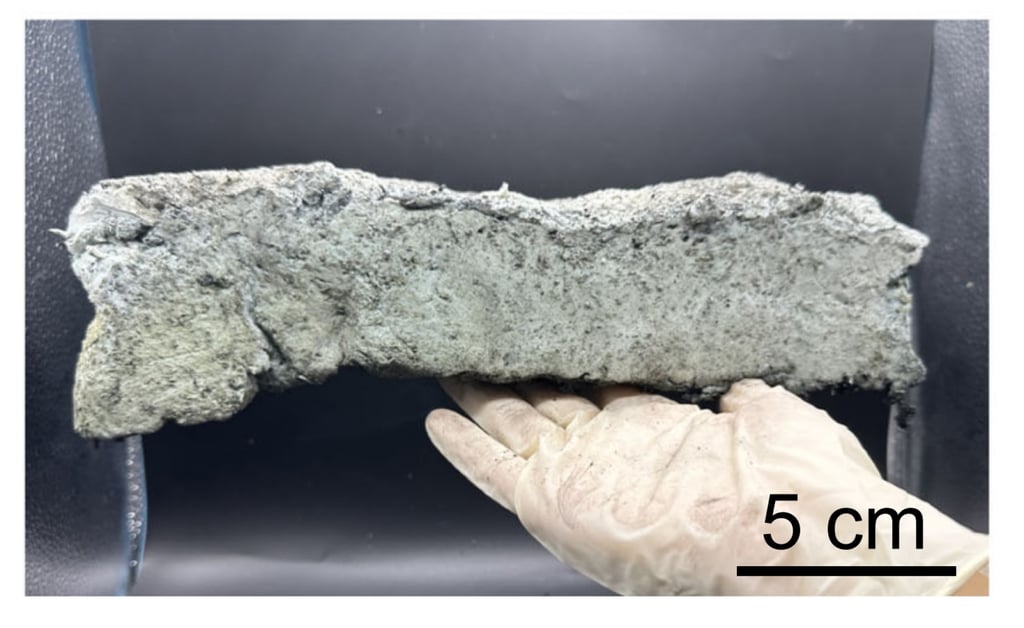

This method involves a rapid combustion reaction between silicon powder and polytetrafluoroethylene (PTFE). Researchers place the powder mix in a reaction boat, and after ignition, the material reaches 1,800 degrees Celsius (3,272 degrees Fahrenheit) within seconds, resulting in a volumetric expansion of 1,076 per cent, producing a sponge-like aerogel at a speed of 16 litres per minute.

“This production method is time-efficient and cost-effective compared to traditional methods such as chemical vapour deposition and carbon thermal reduction. It also features a simple process with low energy consumption, as the combustion reaction is self-sustaining once ignited,” Li said in an official report by CAS.

The resulting SiC aerogel has a porosity of up to 99.6 per cent, high compressibility and reversibility. In the lab test, a piece of SiC paper easily recovers from bending and curling.

These aerogels also maintain their insulating properties up to 1,000 degrees in air and 1,700 degrees in inert atmospheres such as argon, significantly outperforming other lightweight insulation materials like silica aerogels, which lose effectiveness above 700 degrees.

In China, advanced aerogels are already being used in major aerospace projects, such as insulation for the Tianwen-1 mission’s engines, the Chang’e-4 lunar probe’s thermoelectric cells and the Long March 5 rocket’s high-temperature fuel systems.

With this development, Li and his team said they had opened up a new path for mass production and extensive engineering applications of SiC aerogel.

“We are very optimistic about large-scale production of SiC aerogels using the method reported here. We believe the technological breakthrough would enable a wider range of applications for ceramic aerogels in daily life, industry and extreme-condition explorations,” they wrote in the paper.