In the quest to harness the power of the stars, one of the greatest challenges lies not in mastering fusion, but in finding materials strong enough to contain it.

Advertisement

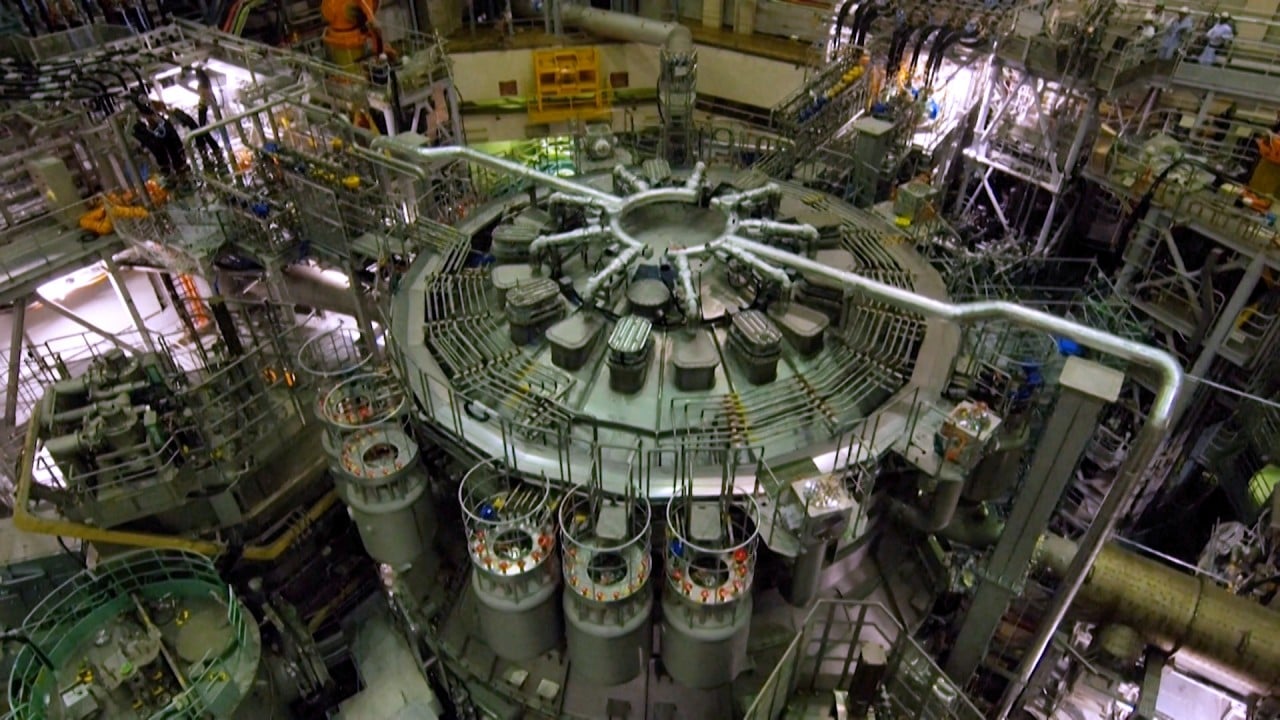

At the heart of a nuclear fusion reactor is an ultra-powerful superconducting magnet, operating at temperatures near absolute zero and under immense magnetic stress. For decades, scientists from around the world have struggled to find materials that simultaneously endure such extreme cold and extreme force.

Chinese scientists have detailed how they created CHSN01 (China high-strength low-temperature steel No 1), deployed it this year in the construction of world’s first fusion nuclear power generation reactor and put China in a leading position in materials science.

It was a decade-long journey marked by setbacks, doubt and ultimate triumph.

In 2011, the International Thermonuclear Experimental Reactor (ITER), which is under construction in southern France, faced a critical material challenge. Testing revealed that the cryogenic steel prepared had become brittle and lost its ductility.

ITER, the world’s largest fusion experiment, was launched in 2006 from a collaboration between seven members, including China.

Advertisement

At the core of the fusion device, superconducting magnets are armoured with cryogenic steel, like a jacket engineered to endure ultra-low temperatures. This material must withstand both liquid helium’s 269 degrees Celsius (516 Fahrenheit) cryogenic environment and the massive Lorentz forces generated by intense magnetic fields.